SKD-90 5 Sides CNC Holes Drilling Machine

SKD-90 CNC drilling machine is the full automatic 5 sides drilling equipment, data can be one time imported to complete six sides holes drilling. It designed with double clampers. Completely solve all positions of drilling. Adopting PA bus control system, with self- development CAD/ CAM software. Machine can be connected with variety brands of production data software to input the production data directly. Highly raising the production efficiency and reducing the daily production costs for the factories.

Patent Design

ZL201610086429.6 / ZL201620120851.4 / ZL201630051400.5

ZL201521020306.X / ZL201530103447.7 /ZL201220736609.1

ZL201420153641.6 / ZL201220738924.8 / ZL201620139335.6

Max.Width of Work-piece: 900mm

Patent Design: ZL201220738924.8

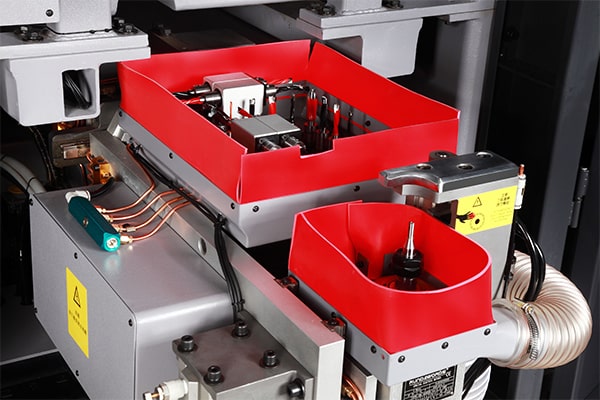

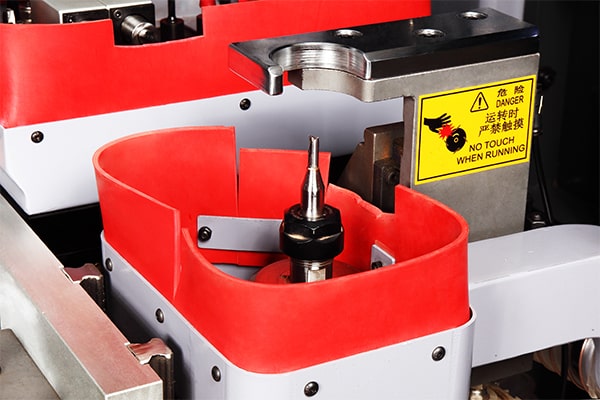

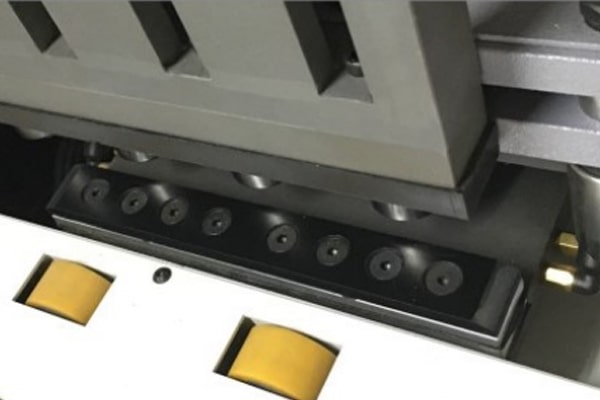

Vertical/Horizontal Drilling Device, Grooving Device. Patent designed U type designed drill chuck.

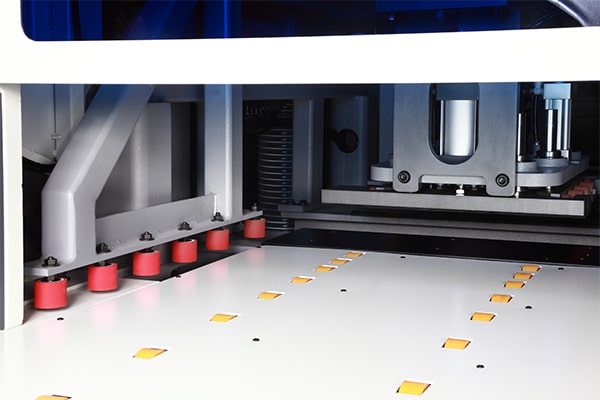

Automatic Clamping and Feeding Device: According to computer drilling program, automatic work-pieces feeding and positioning.

Automatic Side Aligning Device: Automatic control the working stroke of the side baffle, which can adapt to the positioning requirement of different work-pieces width.

Patent Design: ZL201220736609.1

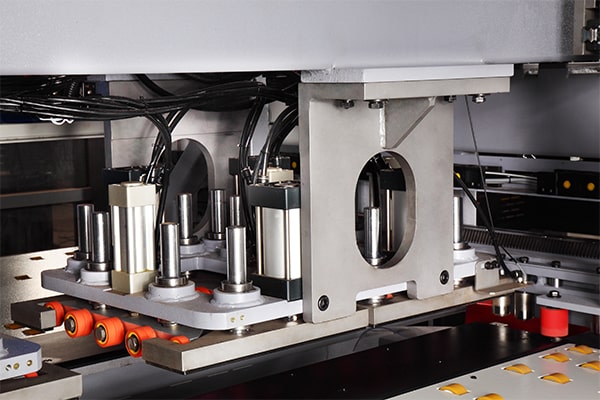

Patented designed. It is a new type CNC drilling machine, which is composed of multi-sliders supporting device. Reduce vibration of drilling and grooving that improve the processing speed and quality.

Patent Design: ZL201420153641.6

Patented design Grooving relocatable baffle device, ensure the accurately size of grooving depth on work-pieces.

Patent Design

201630051400.5

201620139335.6

Patented designed champing device and relocatable champing chuck, when workpiece in high speed feeding, it can reduce the workpiece friction and wearing that protect the surface.

Patent Design: 201521020306.X

Patented Design Roller Type Side Baffle: When workpiece in high speed feeding, it can reduce the friction and wearing between workpiece and side baffle. To protect the side surface of workpiece and realized a higher processing speed.

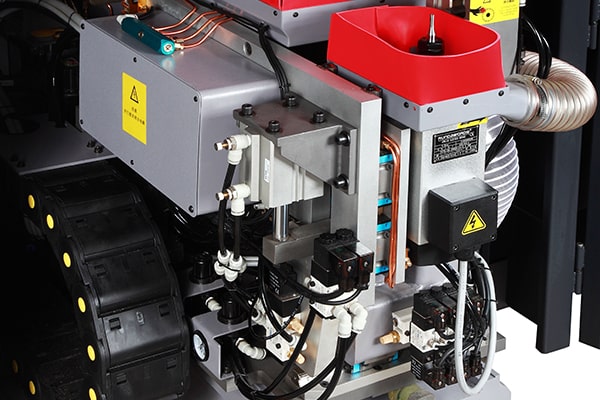

Transmission System: Adopt Taiwan DELTA servo motor control, international famous brand reducer, gear, rack. International famous brand high strength & heavy-duty linear guides and siding carrage. Fully sealing oil seal equiped with central lubricating system. Which ensure the perfect effect of dust-proof.

Automatic Pressing Device: Automatic pressing and loosen the work-pieces according to the computer controlling program, which satisfy the requirement of the drilling and feeding.

Control System: Adopted PA CNC system, Image-text input interface and drilling data can be put by CAD, realize the convenient and rapid operation. It can realize the seamless connect, according to the file format of user production design management software, without separately input data, realize faster drilling processing.

|

Technical Date |

SKD-90 |

|

Working Stroke & Max.Positioning Speed |

|

|

X axis |

1250mm, 90m/min |

|

Y axis |

1490mm, 90m/min |

|

A axis |

80mm, 50m/min |

|

Z axis |

50mm, 50m/min |

|

Drilling Unit |

|

|

U-shaped vertical drilling |

15支pcs |

|

Horizontal spindle |

2 (Left)+2 (Right) and 2 (Front)+2(Back) |

|

Motor power |

2.2kw.4500rpm |

|

Router |

|

|

Router type |

Grooving & Round milling |

|

Tool diameter |

φ6-φ10mm |

|

Tools handle diameter |

1/2 |

|

Motor power |

2.2kw, 24000prm |

|

Processing Size Range |

|

|

Min.width of work-piece |

50mm |

|

Max.width of work-piece |

900mm |

|

Min.length of work-piece |

250mm |

|

Max.thickness of work-piece |

50mm |

|

Other Data |

|

|

Working table height |

950mm |

|

Total power |

8.6kw |

|

Working Voltage |

380V, 50HZ |

|

Air pressure |

0.6-0.8Mpa |

|

Weight |

2200KG |

|

Overall dimensions |

2800*2190*1700mm |

|

Diameter of suction Port |

Φ125x1 |

CONTACT US

GUANGDONG SANDAR CNC MACHINERY CO., LTD.

We provide customers with quality products and services.

If you would like to leave us a comment please go to contact us

© 2019 GUANGDONG SANDAR CNC MACHINERY CO., LTD. All rights received.