SK-3200SP CNC Panel Saw

SK-3200SP CNC Panel Saw is the full automatic cutting equipment that can provide quantity production solutions of panel cutting for furniture manufacturing. Adopting 19" LED screen and PC computer control system, machine can be connected with production data software to input the production data directly. Highly raising the production efficiency and reducing the daily production costs for the factories.

- European technical design

- High precision high efficiency

- Suitable for high precision production requirement.

- Precision, Durable

Max. working size: 3100 x 3100x 90mm

Advanced flange fastening structure, which saw blades installation more convenient. Saw carriage rising rapidly, Max.sawing height: 120mm (install with 450mm blade).

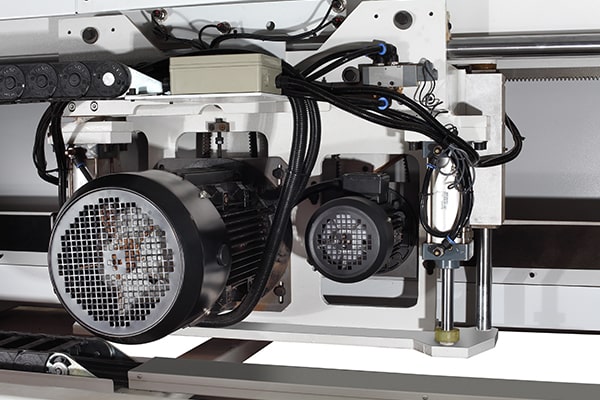

Saw Carriage and Blade Transmission Device: Saw carriage adopts heavy duty cog wheel and gear racks, which support the rapid and stable sawing. The up and down adjustment of main saw and grooving saw controlled by precision cylindrical guide, main and grooving saws driven by independent motor, main saw can automatic adjust rising height according to work-piece thickness.

Side Aligning System: Lateral thrusting by numerical control positioning, more accurately lateral pressing the work-pieces. Pressure can be adjusted according to the work-pieces of different thickness, weight and material ensure the precision of sawing dimension.

PC Computer Controlled System: Equipped with 19”LED screen, prefect Windows control interface, completely functions and diagrams. Which production controller can input the data from the office, realize the long distance control.

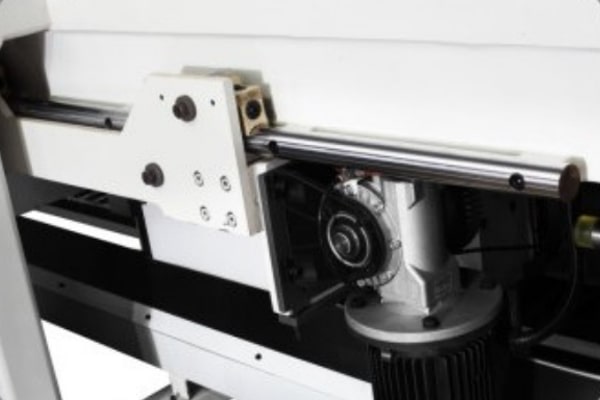

Saw Carriage Sliding Mechanism: Made by precision chromium-plated steel guide wheel and cylindrical guide, which ensure the precision linear motion and low vibration of the saw carriage, realize the accurately sawing.

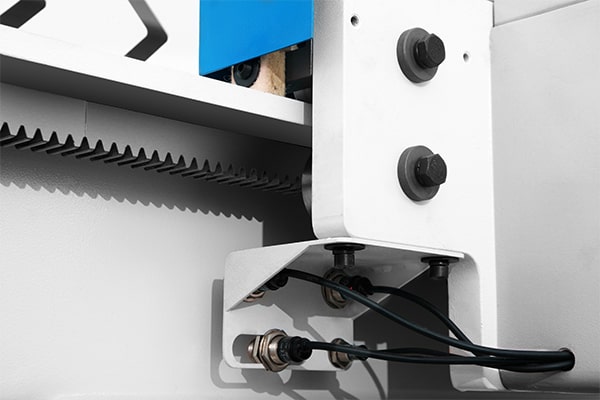

Gripping and Feeding Device: Driven by servo motor, combine with cog wheel and gear racks, realize accurately feeding positioning, ensure the dimensional accuracy of work-pieces.

New Type Grippers: Heavy duty design, with strong gripping strength and feeding strength, ensure the smoothly work-pieces feeding. Optimized design, new type grippers, to realized the min.sawing thickness: 45mm. Working table made by chromed steel plate, with high strength and good wearing resistance. Reducing the friction between work-pieces and table, avoid the surface damage of work-pieces.

Air Floatation Table: Equip with 1 SET of 4KW air pump, table surface install with stainless steel beads, effectively reduce the friction between work-pieces and beads; Auxiliary rollers installs in front of the working tables, convenience for the work-pieces carried up and down and reduce the friction; Emergency stop button installed under the working table, for emergency protection.

|

Technical Data |

SK-3200SP |

|

Max working size |

3100*3100*90mm |

|

Max saw motor |

15kw |

|

Scoring saw motor |

1.5kw |

|

Pusher motor |

2kw |

|

Saw carriage servo motor |

2kw |

|

Max cutting height |

90mm (120mm Optional) |

|

Cutting speed |

Max.85m/min |

|

Saw carriage return speed |

100m/min |

|

Pusher speed |

Max.85m/min |

|

Main saw rev. |

4300rpm |

|

Scoring saw rev. |

5900rpm |

|

Main saw size |

φ400 (φ450 Optional) |

|

Scoring saw size |

φ200mm |

|

Working Voltage |

380V, 50HZ |

|

Air pressure |

6-8kg/cm2 |

|

Total power |

27.3KW |

|

Weight of machine |

5860kg |

|

Diameter of suction port |

Φ200x2, Φ100x2 |

Your cnc woodworking machine supplier is going to have a lot to offer you as they are the face of your business. You need to be able to trust them, and they will also need to be able to trust you. Trust is everything when it comes to building or buying anything, including woodworking machines. When you are ready to move forward with a supplier, there are a few things that you can look for to ensure that they are trustworthy. These things may not guarantee that they are honest or won't rip you off, but you will know that before you ever meet them in person.

The first thing that you can do is research the company. No matter what type of cnc woodworking machine supplier you are working with, you are going to want to find out all the relevant details about them. The easiest way to do this is through the company's website. If you have already checked the site out, this is an even easier option. You can learn all of the important information that you can use to determine if this company is going to be honest and reliable.

Look to see how long the cnc woodworking machine supplier has been in business. If you don't feel comfortable with them, or they are not very professional, you should probably find someone else. The supplier you choose should have a reputation that spans decades in order to be able to stand behind their work and service.

Talk to others that have purchased from the particular company. Find out what they liked and didn't like about their experience with them. You should be able to hear plenty of good things about them if you ask around. By talking to people that have purchased from a particular supplier in the past, you will be able to make a more informed decision and choose the one that you feel will give you the best quality.

Take a look at the types of machines that they provide. While it is a good idea to have a variety of machines available, only choose a supplier that offers the ones that you need. There is no reason to have a large machine collection when you only need a few of them at any given time. You will be able to focus your money on the machine that you need at any given moment in time.

You need to know how stable the financial status of the woodworking machine supplier is. You don't want to get stuck with a company that isn't going to be around in the near future. With that said, the better you feel about their stability, the more likely you are to purchase from them in the future.

CONTACT US

GUANGDONG SANDAR CNC MACHINERY CO., LTD.

We provide customers with quality products and services.

If you would like to leave us a comment please go to contact us

© 2019 GUANGDONG SANDAR CNC MACHINERY CO., LTD. All rights received.