- Home » Product

Product

While CNC refers to the ability to cut and drilling with precision and edging in perfect edge, it also means that each piece you create can be anything you desire. Whether you are creating kitchen cabinet, closets, office furniture, whole house furniture or simple decorative pieces, the choices are endless.

One of the advantages of a CNC machine for woodworking is that each piece will be done precisely and consistently. Since each cutting and drilling is made by machine, each piece is inaccuracy size, the appearance of quality.

Another advantage of a CNC machine for woodworking is that you can now add any finishing you want. You can add a beautiful veneer, or you can choose to do the cutting or edging or drilling in your finished piece and then stain it for a more polished look. This allows you to create different textures and finishes by combining wood, metals, and finishes with some creativity.

With a CNC machine for woodworking, you will not need to worry about the little problems such as tight work. The cuts and holes drilling will be so precise that your joints will close together smoothly. When the cuts or holes are made by hand, there is always the risk of having a few notches and the door will stick in the first few turns.

A CNC machine for woodworking has numerous benefits, but one of the most important advantages is that it will save you money over time. This is because you will not need to buy the tools that you normally would in order to create the pieces you want. Less machines, but high production efficiency.

If you are interested in using a CNC machine for woodworking, you can check out the SANDAR manufacturers of these machines online. Most major woodworking supply stores sell CNC machines for woodworking, and you can easily find one to fit your needs.

If you are a professional woodworker or furniture manufacturers, or if you just want to create your own unique pieces, a CNC machine for woodworking is the perfect solution. Even though you will not be able to create the intricate design you would like with the help of a computer, you will be able to create beautiful pieces that are the envy of all your friends.

-

DW-642 Heavy-duty Automatic Six Rows Boring Machine (With Automatic Feeding Device)

Heavy-duty automatic six rows boring machine (with automatic feeding device).

-

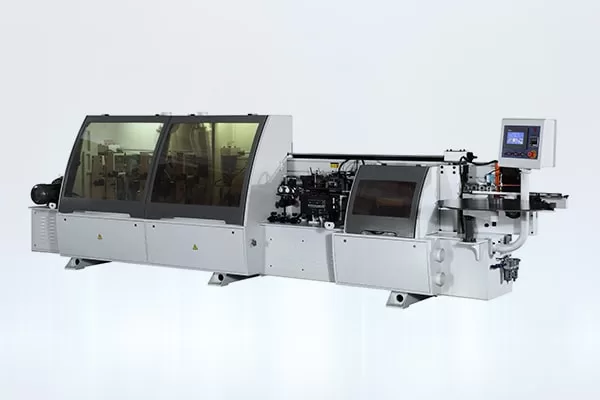

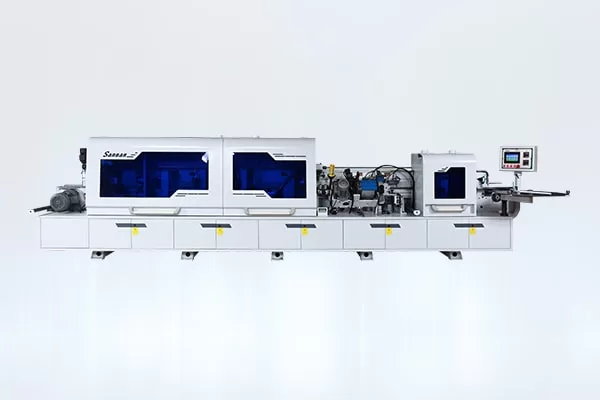

SE-108TA Automatic Edge Banding Machine

SE-108TA edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Main function:Pre-milling, double gluing & Edging, end trimming, rough trimming, fine trimming, corner rounding scrapping, buffing.

-

SK-2800SP CNC Panel Saw

SK-2800SP CNC Panel Saw is the full automatic cutting equipment that can provide quantity production solutions of panel cutting for furniture manufacturing. Adopting 19″ LED screen and PC computer control system, machine can be connected with production data software to input the production data directly. Highly raising the production efficiency and reducing the daily production costs for the factories.

-

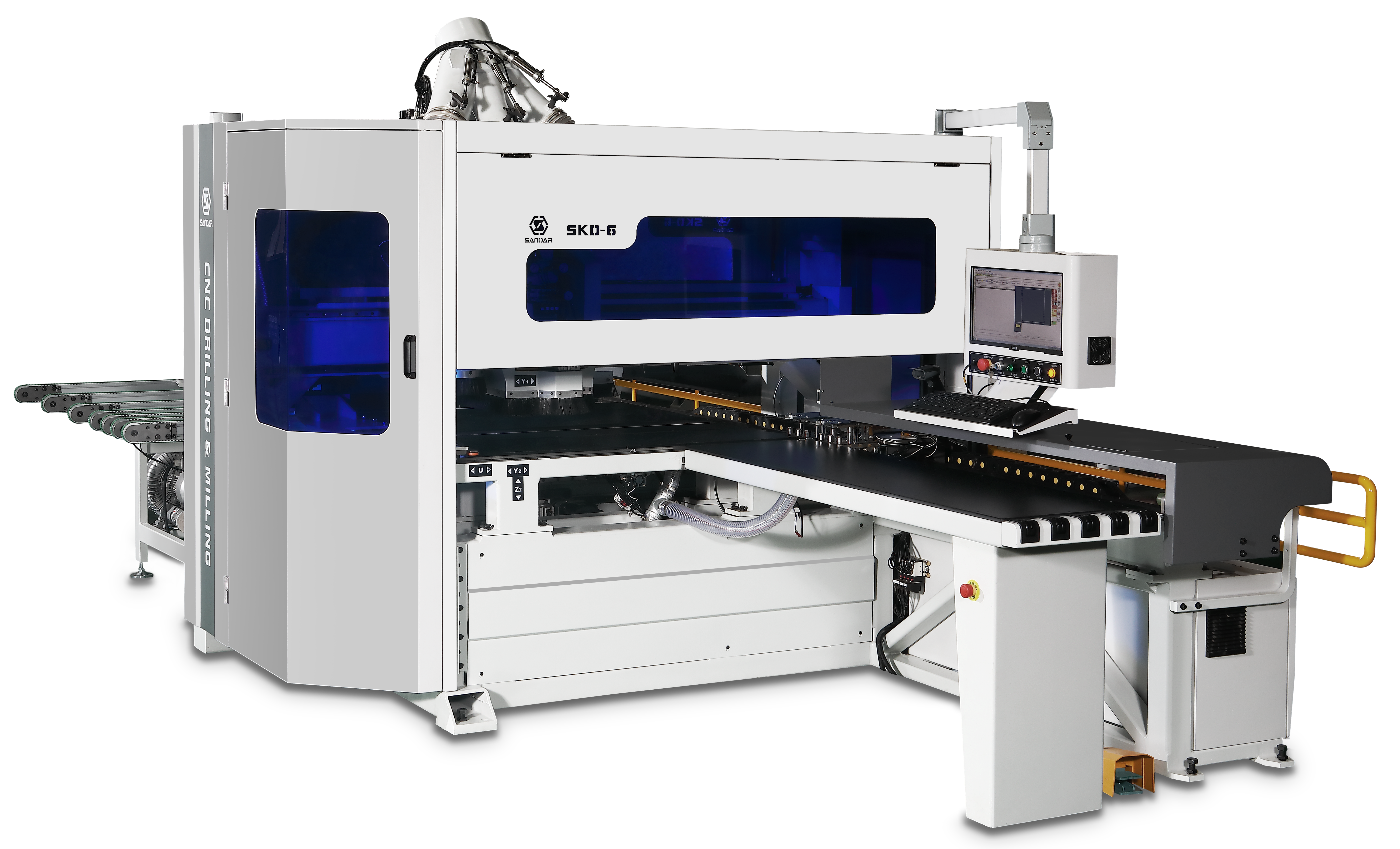

SKD-6/2 6 Sides Double Working Area CNC Drilling Machine

SKD-6/2 6 Sides CNC drilling machine is the full automatic drilling /Boring equipment,designed with 2 top and 2 bottom drilling, 2top and 2 bottom milling device, that can provide the complete solutions of synchronous 6-sides holes drilling, top & bottom sides grooving/Milling for panel-type furniture manufacturing.

Heavy-duty structure designed, Adopting GERMAN bus control system. Machine can be connected with variety brands of production design data software,which can input the production data directly. Highly raising the production efficiency and reducing the daily production cost & labor costs for the factories.

-

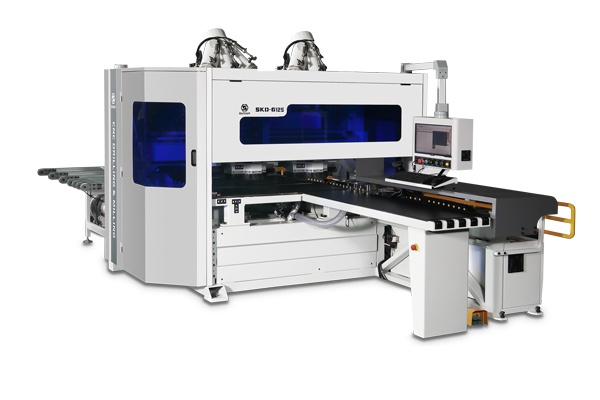

SKD-6125L 6 Sides CNC Drilling Machine

SKD-6125L 6 Sides CNC drilling machine is the full automatic drilling /Boring equipment,designed with 2 top and 1 bottom drilling, 1 top and 1 bottom milling device, that can provide the complete solutions of synchronous 6-sides holes drilling, top & bottom sides grooving/Milling for panel-type furniture manufacturing. Heavy-duty structure designed, Adopting GERMAN bus control system. Machine can be connected with variety brands of production design data software,which can input the production data directly. Highly raising the production efficiency and reducing the daily production cost & labor costs for the factories.

-

SKL-2613EL CNC Labeling & Processing Center

SKL-2613EL CNC Labeling & Processing Center is the full automatic multi-functions equipment that can provide users with auto labeling, routing, milling. Cutting and drilling for different kinds of furniture and solid wood panels. Adopting GERMAN control system, machine can be connected with variety brands of production data software to input the production data directly. Highly raising the production efficiency and reducing the daily production costs for the factories.

-

SW-400NC Sliding Table Saw with NC Control Rip Cut Fence

SW-400NC with NC rip cut fence controlled. The real precision sliding table saw and industry recognized good saw.

-

DW-422 Heavy-duty Automatic Six Rows Boring Machine (With Automatic Feeding Device)

Heavy-duty automatic four rows boring machine.

-

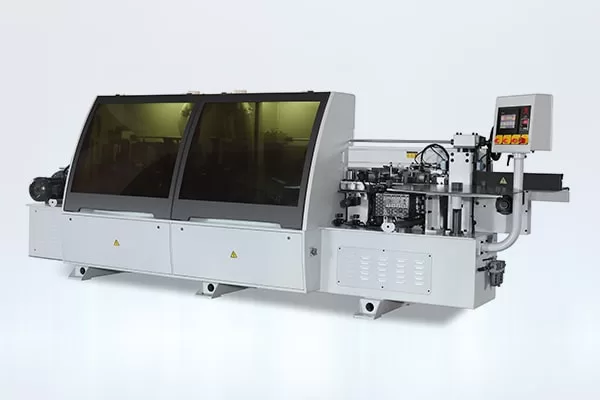

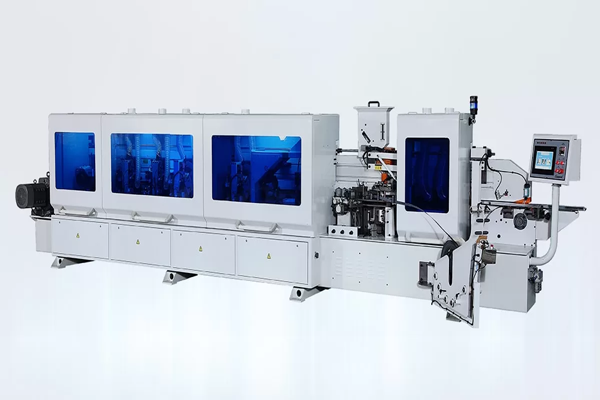

SE-108B Heavy-duty Automatic Edge Banding Machine

SE-108B edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. With patented appearance design and imported famous brands of key components, machines can offer a high efficiency and stable performance with high precision for the entire production process. Function??Pre-milling, gluing & Edging, end trimming, rough trimming, fine trimming, corner rounding scrapping, buffing.

-

SK-3200SP CNC Panel Saw

SK-3200SP CNC Panel Saw is the full automatic cutting equipment that can provide quantity production solutions of panel cutting for furniture manufacturing. Adopting 19″ LED screen and PC computer control system, machine can be connected with production data software to input the production data directly. Highly raising the production efficiency and reducing the daily production costs for the factories.

-

SKD-6L Six Sides CNC Drilling Machine

SKD-6L Six Sides CNC drilling machine is the full automatic drilling /Boring equipment, that can provide the complete solutions of synchronous 6-sides holes drilling, top & bottom sides grooving/Milling for panel-type furniture manufacturing. Heavy-duty structure designed, Adopting GERMAN bus control system. Machine can be connected with variety brands of production design data software,which can input the production data directly. Highly raising the production efficiency and reducing the daily production cost & labor costs for the factories.

-

SKL-2613E CNC Processing Center

SKL-2613E CNC Processing Center is the full automatic multi-functions equipment that can provide users with auto labeling, routing, milling. Cutting for different kinds of furniture and solid wood panels. Adopting GERMAN control system, machine can be connected with variety brands of production data software to input the production data directly. Highly raising the production efficiency and reducing the daily production costs for the factories.

-

SW-400B High Precision Sliding table Saw With 45?? Tilting Saw Blade

The real precision sliding table saw and industry recognized good saw.

-

DW-610 Six Rows Boring Machine

Six rows boring machine, Vertical rows had two motors.

-

SE-107B Automatic Edge Banding Machine

SE-107B edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Function??Gluing & Edging, end trimming, rough trimming, fine trimming, corner rounding scrapping, buffing.

-

SK-3800SP CNC Panel Saw

SK-3800SP CNC Panel Saw is the full automatic cutting equipment that can provide quantity production solutions of panel cutting for furniture manufacturing. Adopting 19″ LED screen and PC computer control system, machine can be connected with production data software to input the production data directly. Highly raising the production efficiency and reducing the daily production costs for the factories.

-

SKL-2513-12T/SKL-2513/2 CNC Processing Center

SKL-2513-12T with 9KW Spindle + tools changer device

SKL-2513/2 Installed with 6 KW x 2 Spindles.

-

SW-400C High Precision Sliding Table Saw (90°)

The real precision sliding table saw and industry recognized good saw.

-

DW-606 Six Rows Boring Machine

Six rows boring machine, Vertical row with one motor.

-

SE-106B Automatic Edge Banding Machine

SE-106B edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Main Functions: Pre-milling, gluing & Edging, end trimming, rough trimming, fine trimming, scrapping, buffing.

-

SK-3800TP-A Automatic CNC Panel Saw (Rear Feeding)

SK-3800TP-A CNC Panel Saw is the full automatic cutting equipment that can provide the quantity production of panel cutting for custom furniture manufacturing. Adopting 19″ LED screen and PC computer control system, machine can be connected with variety brands of production data software to input the production data directly. Highly raising the production efficiency and reducing the daily production costs for the factories.

-

SKD-6R 6 Sides CNC Drilling Machine

SKD-6R Six Sides CNC drilling machine is the full automatic drilling /Boring equipment,designed with 1top and 1 bottom drilling and milling device, that can provide the complete solutions of synchronous 6-sides holes drilling, top & bottom sides grooving/Milling for panel-type furniture manufacturing. Heavy-duty structure designed, Adopting GERMAN bus control system. Machine can be connected with variety brands of production design data software,which can input the production data directly. Highly raising the production efficiency and reducing the daily production cost & labor costs for the factories.

-

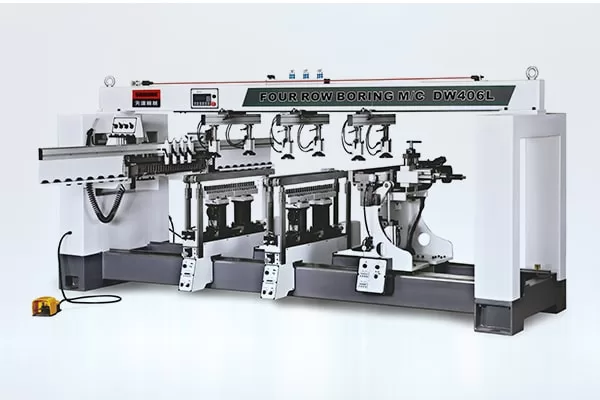

DW-406L Four Rows Boring Machine

Four rows boring machine with Convertibled drill rows

-

SE-105B Automatic Edge Banding Machine

SE-105B edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Main Functions

Gluing & Edging, end trimming, rough trimming, fine trimming, scrapping, buffing.

-

SKD-150/2 5 Sides CNC Drilling Machine for Wood

SKD-150/2 CNC drilling machine is the full automatic 5 sides drilling equipment, data can be one time imported to complete six sides holes drilling. It designed with double position operation areas, which is the first model lanch into Market in China. Completely solve all positions of drilling. Adopting Germany brands bus control system, with self- development CAD/ CAM software. Machine can be connected with variety brands of production data software to input the production data directly. Highly raising the production efficiency and reducing the daily production costs for the factories.

-

SKD-6125R Six Sides CNC Drilling Machine

SKD-6125R 6 Sides CNC drilling machine is the full automatic drilling /Boring equipment,designed with 2 top and 1 bottom drilling, 1 top and 1 bottom milling device, that can provide the complete solutions of synchronous 6-sides holes drilling, top & bottom sides grooving/Milling for panel-type furniture manufacturing. Heavy-duty structure designed, Adopting GERMAN bus control system. Machine can be connected with variety brands of production design data software,which can input the production data directly. Highly raising the production efficiency and reducing the daily production cost & labor costs for the factories.

-

DW-305 Three Rows Boring Machine

Three rows boring machine,Vertical row with two motors.

-

SE-104B Automatic Edge Banding Machine

SE-104B edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Main function??Gluing & Edging, end trimming, fine trimming, scrapping, buffing.

-

SE-106JS Beveled Edge Banding Machine

SE-106JS edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. With patented appearance design and imported famous brands of key components, machines can offer a high efficiency and stable performance with high precision for the entire production process.

Edge Banding Machine Glue, the most important position or the most important part, the first thing is to rub the sheet, it is necessary to uniform, continuously, so that it can guarantee full adhesion to the side strip.

-

SKD-125S 5 Sides CNC Wood Drilling Machine- Double clampers

SKD-125S CNC drilling machine is the full automatic 5 sides drilling equipment, data can be one time imported to complete six sides holes drilling. It designed with double clampers. Completely solve all positions of drilling. Adopting Germany brands bus control system, with self- development CAD/ CAM software. Machine can be connected with variety brands of production data software to input the production data directly. Highly raising the production efficiency and reducing the daily production costs for the factories.

-

DW-303 Three Rows Boring Machine

DW-303 boring machine, wtih 1 Horizontal drill row + 2 Vertical rows

-

SE-2105B Automatic Double Sides Edge Banding Machine

SE-2015B double sides edge banding, application for one time finished two sides edging. Suitable for standard product and quantity production requirement. Main function : 2 SETS of Gluing & edging, end trimming, rough trimming, fine trimming, scraping, buffing.

-

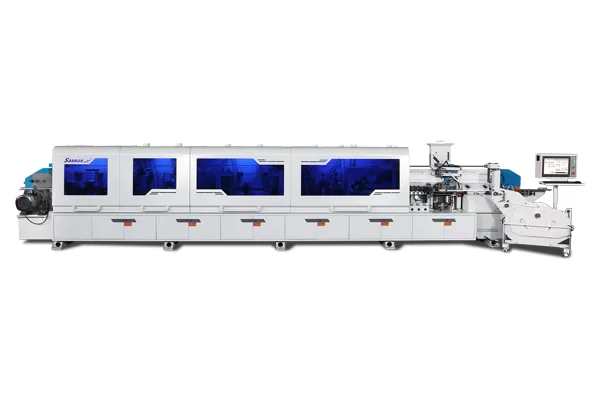

SE-206P Heavy-duty High Speed Automatic Edge Banding Machine

SE-206P edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Max. feeding speed: 26m/min. Main Functions: Pre-milling, Quick melt gluing & Edging, pneumatic end trimming, pneumatic trimming1, pneumatic trimming2, pneumatic scrapping1, pneumatic scrapping2, buffing1, buffing 2.

-

SE-2106B Automatic Double Sides Edge Banding Machine -

SE-2015B double sides edge banding, application for one time finished two sides edging. Suitable for standard product and quantity production requirement. Main function : 2 SETS of Pre-milling, gluing & edging, end trimming, rough trimming, fine trimming, scraping, buffing.

-

SKD-125 Five Sides CNC Drilling Machine

D-125 CNC drilling machine is the full automatic 5 sides drilling equipment, data can be one time imported to complete six sides holes drilling. Completely solve all positions of drilling. Adopting PA bus control system, with self- development CAD/ CAM software. Machine can be connected with variety brands of production data software to input the production data directly. Highly raising the production efficiency and reducing the daily production costs for the factories.

-

SE-208B Heavy-duty High Speed Automatic Edge Banding Machine

SE-208P edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Main Functions: Pre-milling, quick melt gluing & Edging, pressure roller glue scraping device, pneumatic trimming1 , pneumatic trimming2, corner rounding, pneumatic scraping1, pneumatic scraping 2, edge band clamping unit, buffing1, buffing 2.

-

SKD-90 5 Sides CNC Holes Drilling Machine

SKD-90 CNC drilling machine is the full automatic 5 sides drilling equipment, data can be one time imported to complete six sides holes drilling. It designed with double clampers. Completely solve all positions of drilling. Adopting PA bus control system, with self- development CAD/ CAM software. Machine can be connected with variety brands of production data software to input the production data directly. Highly raising the production efficiency and reducing the daily production costs for the factories.

-

SE-208TA Heavy-duty High Speed Automatic Edge Banding Machine

SE-208TA edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Main Functions: Pre-milling, quick melt gluing & Edging1 , quick melt gluing & Edging2, pressure roller glue scraping device, pneumatic trimming1 , pneumatic trimming2, corner rounding, pneumatic scraping1, pneumatic scraping 2, edge band clamping unit, buffing1, buffing 2.

CONTACT US

GUANGDONG SANDAR CNC MACHINERY CO., LTD.

We provide customers with quality products and services.

If you would like to leave us a comment please go to contact us

© 2024 GUANGDONG SANDAR CNC MACHINERY CO., LTD. All rights received.