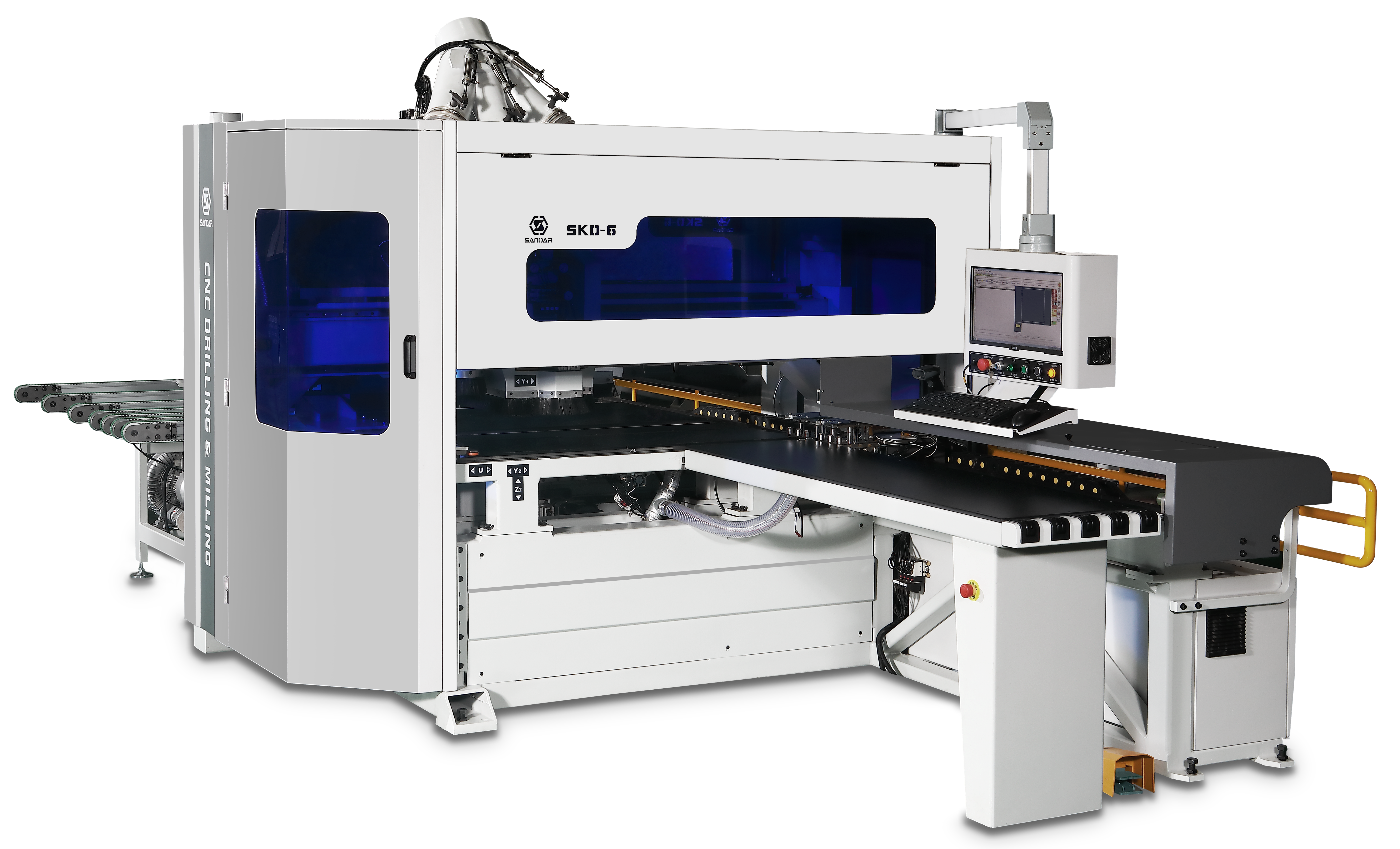

SKD-6R 6 Sides CNC Drilling Machine

SKD-6R Six Sides CNC drilling machine is the full automatic drilling /Boring equipment,esigned with 1top and 1 bottom drilling and milling device, that can provide the complete solutions of synchronous 6-sides holes drilling, top & bottom sides grooving/Milling for panel-type furniture manufacturing.

Heavy-duty structure designed, Adopting GERMAN bus control system. Machine can be connected with variety brands of production design data software,which can input the production data directly. Highly raising the production efficiency and reducing the daily production cost & labor costs for the factories.

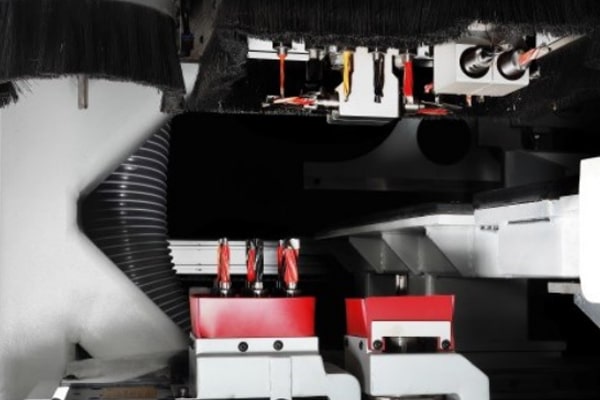

Right side controller, designed with 1 Top + 1Bottom, Drilling & Milling Device

SKD-6R Six Sides CNC drilling machine is the full automatic drilling /Boring equipment,esigned with 1top and 1 bottom drilling and milling device.

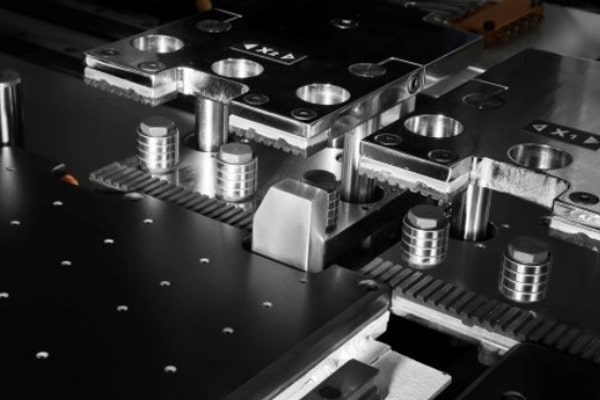

Double Clamping Device: Min.workpiece Size 35x250mm

Movable Air Floating Working Table (Patented Designed)

Servo Controlled Automatic Side Aligning Device

Cross Conveyor Rear Outfeeding Table

Up & Down Vertical/Horizontal Drilling Device, Grooving Device.

Sealed Multi Point controlled Dust Collection Cover

1. Adopt Germany bus controlled CNC system, integrated Self-developed CAD/CAM Software that carry out sheet metal graphical editing and directly generate NC Program for Processing.

2. Machinery can connect with variety brands of production data software.

3. The precision processed heavy- duty frame and components.

4. Extended 5900mm guide rail, application for processing work-piece without length limitation.

5. Data can be one time imported to complete the six sides drilling.

6. Symmetrical holes and grooves at two sides of panel can be processed synchronously.

7. Machine is able to process stacked panels (two pieces synchronously) with mirror layout of holes and grooves.

|

Technical Date |

SKD-6R |

|

Working Stroke & Max.Positioning Speed |

|

|

X axis (5900mm guide rail) |

X1: 3800mm, 130m/min X2: 4500mm, 130m/min |

|

Y axis |

Y1:1640 mm, 110m/min Y2:1460 mm, 110 m/min |

|

Z axis |

Z1/Z2:90 mm, 50 m/min |

|

U axis |

1240mm,90m/min |

|

Upper Drilling Unit |

|

|

Drill chuck quantity |

1pcs |

|

Vertical drilling |

6X+6Y |

|

Horizontal spindle |

2L+2R, 2F+2B |

|

Motor power |

2.2KWx2, 4500rpm |

|

Bottom Drill Unit |

|

|

Vertical drilling |

3×3 Matrix distribution |

|

Motor power |

2.2KW, 4500rpm |

|

Router |

|

|

Router quantity |

1UP+1Bottom |

|

Router type |

Grooving & Round milling |

|

Tool diameter |

Ф6-Ф12mm(Tools optional) |

|

Tools handle diameter |

1/2 |

|

Motor power |

3.5kwx24,000rpm |

|

Processing Size Range |

|

|

Min.width of work -piece |

35mm |

|

Max.width of work -piece |

1250mm |

|

Min.Length of work -piece |

250mm |

|

Max.thickness of work -piece |

60mm |

|

Other Data |

|

|

Working table height |

900mm |

|

Total power |

23.5kw |

|

Working Voltage |

380V, 50HZ |

|

Air pressure |

0.6-0.8Mpa |

|

Overall dimensions |

6050x2770x2200mm (length*width*height) |

|

Diameter of suction port |

Ф200mmx1, Ф125mmx1 |

CONTACT US

GUANGDONG SANDAR CNC MACHINERY CO., LTD.

We provide customers with quality products and services.

If you would like to leave us a comment please go to contact us

© 2024 GUANGDONG SANDAR CNC MACHINERY CO., LTD. All rights received.