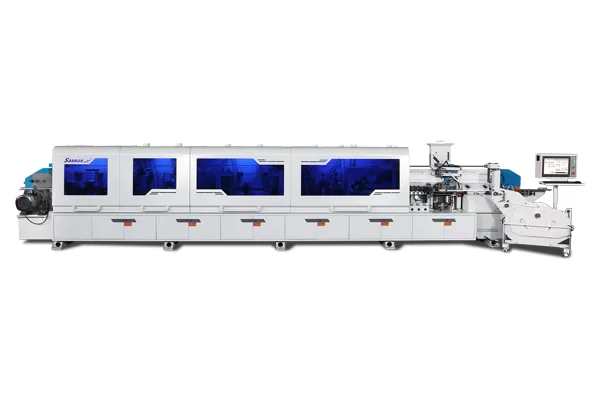

SE-208B Heavy-duty High Speed Automatic Edge Banding Machine

SE-208TA edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Designed with double quick-melt glue pot. Max. feeding speed: 26m/min. With patented appearance design and imported famous brands of key components, machines can offer a high efficiency and stable performance with high precision for the entire production process.

Main Functions

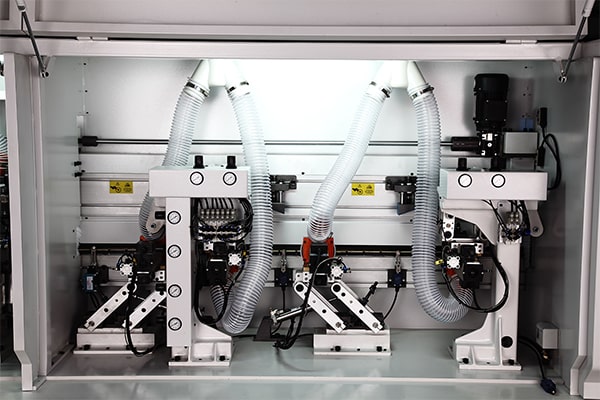

Pre-milling, quick melt gluing & Edging, pressure roller glue scraping device, pneumatic trimming1 , pneumatic trimming2, corner rounding, pneumatic scraping1, pneumatic scraping 2, edge band clamping unit, buffing1, buffing 2.

PC Auto-counter: Interface visualization is more intuitive, more convenient to operate with the use of the length (meter) of the edge band daily count and workpiece daily processing (surface) statistics function.

Double Edge Band Loading Device: Loading disc can install two rolls of edge band tape, when each of them finished, the color alarm lamp will light up.

Automatic Lubrication System: It can automatic lubricating the guide rails on end trimming unit, to make sure its smoothly sliding.

Quick Corner Trimming: Adopt 4 SETS of high speed round contouring trimming device, realize the stable and rapid corner trimming.

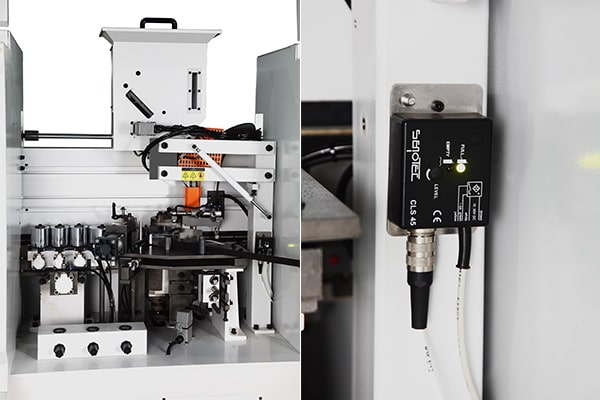

Quick Melt Gluing (with automatic heat preservation function): Installed with Germany import liquid level controlled, accurately control the additive glue amount. Realize the continuously heating control, and satisfy the requirement of high speed edging and gluing.

Motor Frequency Conversion Device: Each trimming unit controlled by independent converter (Except for buffing and scraping unit), effectively reduce the maintenance cost.

|

Model |

Buffing2 |

Buffing1 |

Flat Scraping |

Pneumatic Scraping2 |

Pneumatic Scraping1 |

Four cutters corner trimming |

Pneumatic Trimming2 |

Pneumatic Trimming1 |

End Trimming |

Quickmelt and Edging |

Pre-milling |

|

SE-208P |

• |

• |

• |

• |

• |

• |

• |

• |

• |

• |

• |

|

Technical Data |

SE-208P |

|

Edge band thickness |

0.4-3mm |

|

Work-piece thickness |

10-60mm |

|

Converyor speed |

20m/23m/26m/min |

|

Min. width of work-piece |

60mm |

|

Min. work-piece Length (Without using pre-milling) |

160mm |

|

Min. work-piece Length (Using pre-milling) |

≥230mm |

|

Total power |

21.5kw |

|

Working voltage |

380V,50HZ |

|

Air pressure |

0.7Mpa |

|

Weight |

3580kg |

|

Packing size |

9250*1050*1850mm |

|

Diameter of suction port |

Φ100×8 |

CONTACT US

GUANGDONG SANDAR CNC MACHINERY CO., LTD.

We provide customers with quality products and services.

If you would like to leave us a comment please go to contact us

© 2024 GUANGDONG SANDAR CNC MACHINERY CO., LTD. All rights received.