SKL-2613EL CNC Labeling & Processing Center

Patented Design Number:

ZL201610086001.1

ZL201620120853.3

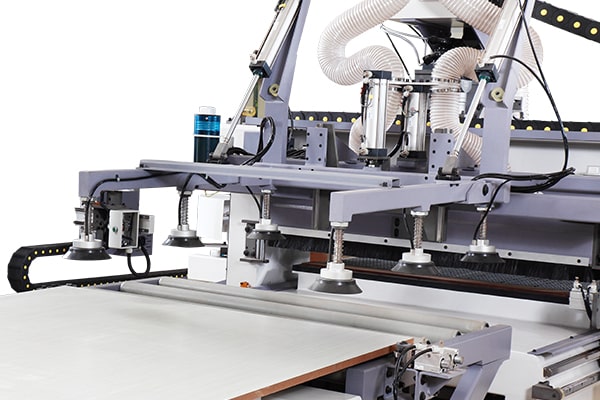

SKL-2613EL CNC Labeling & Processing Center is the full automatic multi-functions equipment that can provide users with auto labeling, routing, milling. Cutting and drilling for different kinds of furniture and solid wood panels. Adopting GERMAN control system, machine can be connected with variety brands of production data software to input the production data directly. Highly raising the production efficiency and reducing the daily production costs for the factories.

Technical Feature

Adopt German control system, integrated CAM software that can carry out sheet metal graphical editing and diretly generate NC program for processing.

Machinery can connect with variety brands of production data software, directly import production data, realizes intelligent seamless connecting to production.

Automatic production code printing & labeling, which adapt to digital production management, increase efficiency of the production management.

Device that with patented design can enhance machinery automation. It can finish automatic high speed cutting, drilling and milling, meanwhile, auto feeding, working table cleaning and out feeding can operate and finish at the same time. Which save processing time and increase production.

Patented Design Number:

ZL201521020475.3

ZL2015110082407

ZL20153263-2

Automatic Feeding Device: Innovative designed auto pick up system. Workpiece can rapidly be pick up by vacuum suction, and positioned accuracy at the cutting baseline on working table, which save feeding time.

Automatic Cleaning Device: Patented designed dust exhaust system installed with sweep rollers. When workpiece in processing, working table can be automatic cleaned at the same time, which save cleaning time.

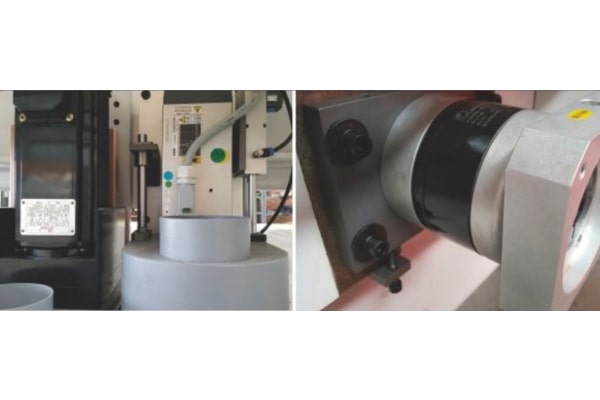

Main Components: Adopt Italian main spindle, German guide rail, TAIWAN DELTA servo motor control, TAIWAN drill chuck and international famous brand reducer.

Control System: Consist of 17 inch color screen display control, wireless mouse, wireless keyboard and USB interfaces. Adopted Germany BECKHOFF numerical control system, Image-text input interface, Data can be imported by CAD, which operation is convenient and rapid.

Automatic Tools Changer

Precision Routing, Milling & Drilling Device: Application for workpieces accuracy cutting and drilling.

| Max table load | 3 Ton |

| Total power | 1.5kw |

| Voltage | 380V, 50Hz |

| weight | 970kg |

| Machine size | 2500*1300*500mm |

| Total power | 0.75kw |

| Voltage | 380V, 50Hz |

| Weight | 400kg |

| Machine size | 3112*1560*860mm |

Out feeding conveyor installed with automatic induction system, which can auto control the conveyor start or stop. More convenient for workers operation.

Labeling Device

Auto Labeling Device: It is with servo motor. Installed with advance automatic alignment device, when workpieces is positioned at the cutting baseline onto to lifting table. It can accurately labeling the mark onto workpiece, which effectively avoid the subsequent processing path and protect the labeling mark.

| X axis | 3000mm, 86m/min |

| Y axis | 1280mm, 86m/min |

| Total power | 2.2kw |

| Working Voltage | 0.6-0.8Mpa |

| Weight | 1260kg |

| Machine size | 3400*1800*1800mm |

CONTACT US

GUANGDONG SANDAR CNC MACHINERY CO., LTD.

We provide customers with quality products and services.

If you would like to leave us a comment please go to contact us

© 2024 GUANGDONG SANDAR CNC MACHINERY CO., LTD. All rights received.