- Home » Edge Banding Machine

Edge Banding Machine

In the past few years, the demand for the edge banding machine has increased to a greater extent. This machine is specially designed to make the banding process much easier. You can find both manual and automatic edge banding machines in the market. However, the automatic edge banding machines have become the No.1 choice of industries. It’s because automatic machines provide the perfect high-quality outcome on the workpiece as compared to manual ones. Here in this article, we will share a few things that you must keep in view when purchasing an edge banding machine. Let’s have a look at these things.

1. The selection of an edge banding machine is usually based on the shape of the workpiece that needs to be machined, productivity, and the type of sealing material.

2. If you are buying this machine for office cabinets and furniture and other similar products, then consider its yield and a few features, such as ABS or PVC scraper device for material sealing, solid wood edge, and finishing knife & sanding device. To ensure that edge’s quality is not influenced by low temperatures during winters, consider looking for an edge banding machine that has a far-infrared preheating device. Other useful configurations options are edge banding machine cutter device and automatic tracking fillet trimming function.

3. The automatic edge banding machine is equipped with several functions, including pre-milling, edge, glue, blunt, refinement, rough trimming, scraping, tracking, polishing, and slotting. All these functions help achieve high efficiency, high precision, beauty, and automation. Also, these features depend on different types of division, including both simple and comprehensive. The simple division is with scraping, glue block, finishing, polishing, and other functions.

4. In general, the use of an automatic edge banding machine and manual edge banding machine can fulfill the needs of a general product in addition to improving its efficiency and reducing production costs.

5. Automatic edge banding machine can have several functions, including preheating, trimming, glue, polishing, and scraping. So, analyze your requirements and ensure to choose a machine that has the required features.

6.Carefully read the manufacturer’s machine information, like its specifications, operation methods, performance, price, and use before making any decision.

Which Edge Banding Machine to Choose?

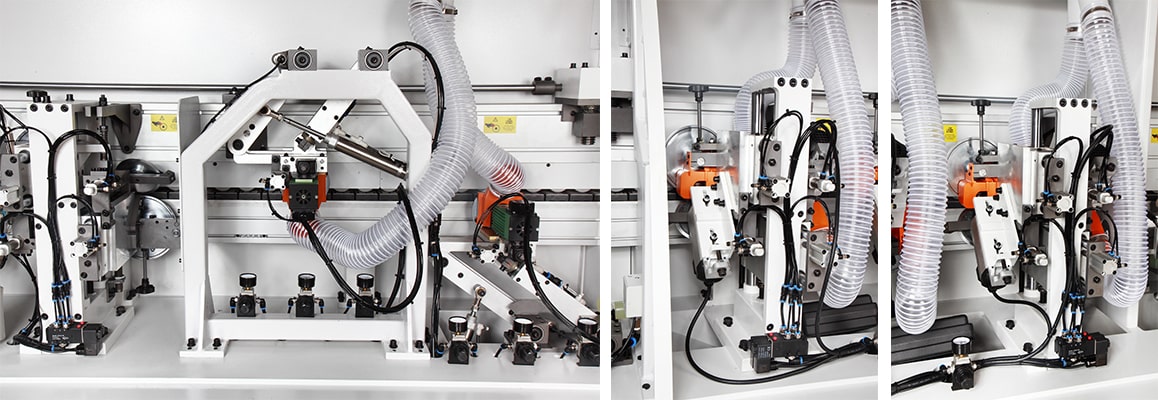

Guangdong Sandar CNC Machinery Co., Ltd. is a professional manufacturer of CNC woodworking machines in China. Sandar uses advanced core technology of software and hardware in the manufacturing process along with several patented designs. This is why its edge banding machines have high-efficiency, excellent appearance, technical contents, stable performance, and reliable quality. The main functions of its automatic edge banding machines include pre-milling, gluing and edging, rough trimming, end trimming, fine trimming, buffing, and corner rounding scrapping. The competitive advantage of choosing Sandar edge banding machine over others include:

- Novel patented and beautiful exterior design

- Use imported components of popular brands

- Use a heavy-duty frame

- Offer machines with various configuration options to fulfill different production requirements of customers

- Machines are controlled by a single encoder with one limit switch. It means the entire edging process will be finished on receiving one signal.

-

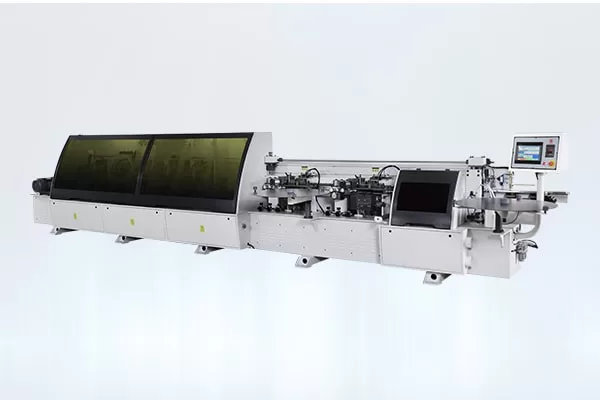

SE-108TA Automatic Edge Banding Machine

SE-108TA edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Main function:Pre-milling, double gluing & Edging, end trimming, rough trimming, fine trimming, corner rounding scrapping, buffing.

-

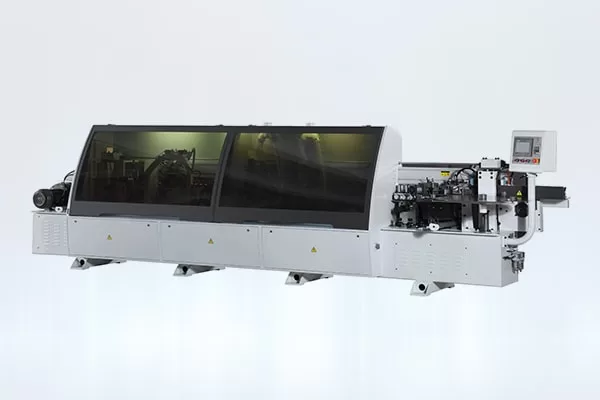

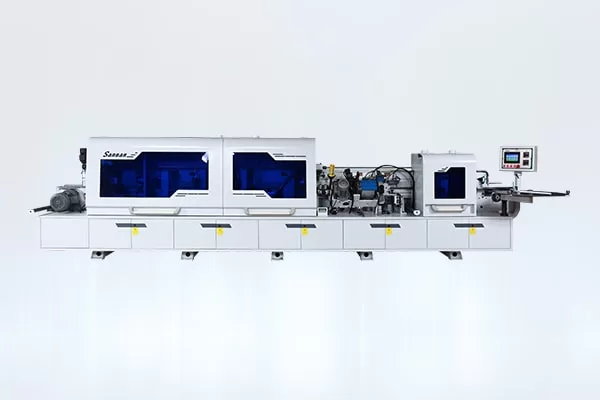

SE-108B Heavy-duty Automatic Edge Banding Machine

SE-108B edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. With patented appearance design and imported famous brands of key components, machines can offer a high efficiency and stable performance with high precision for the entire production process. Function??Pre-milling, gluing & Edging, end trimming, rough trimming, fine trimming, corner rounding scrapping, buffing.

-

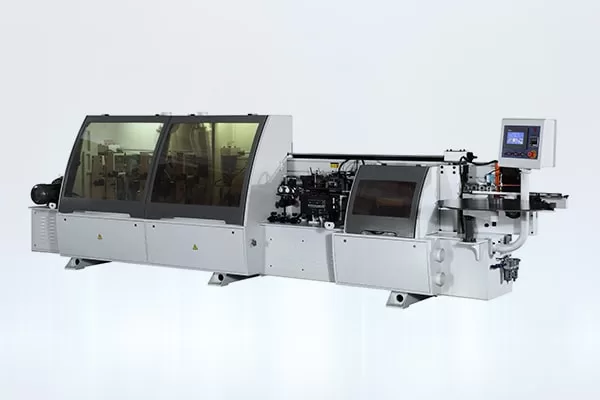

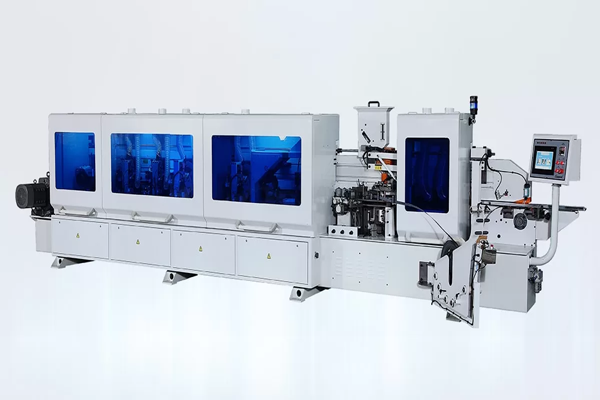

SE-107B Automatic Edge Banding Machine

SE-107B edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Function??Gluing & Edging, end trimming, rough trimming, fine trimming, corner rounding scrapping, buffing.

-

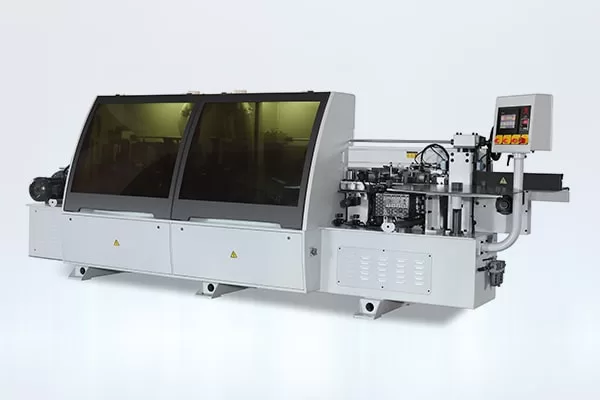

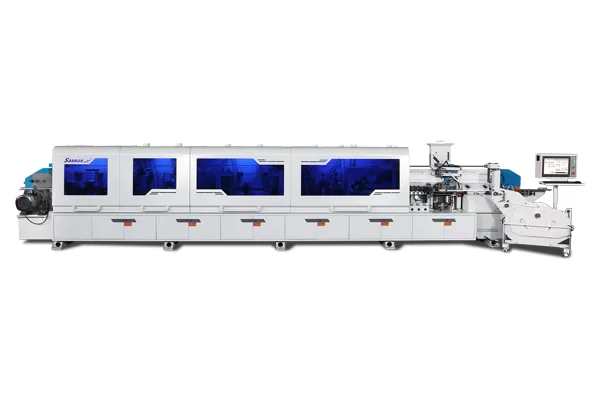

SE-106B Automatic Edge Banding Machine

SE-106B edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Main Functions: Pre-milling, gluing & Edging, end trimming, rough trimming, fine trimming, scrapping, buffing.

-

SE-105B Automatic Edge Banding Machine

SE-105B edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Main Functions

Gluing & Edging, end trimming, rough trimming, fine trimming, scrapping, buffing.

-

SE-104B Automatic Edge Banding Machine

SE-104B edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Main function??Gluing & Edging, end trimming, fine trimming, scrapping, buffing.

-

SE-106JS Beveled Edge Banding Machine

SE-106JS edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. With patented appearance design and imported famous brands of key components, machines can offer a high efficiency and stable performance with high precision for the entire production process.

Edge Banding Machine Glue, the most important position or the most important part, the first thing is to rub the sheet, it is necessary to uniform, continuously, so that it can guarantee full adhesion to the side strip.

-

SE-2105B Automatic Double Sides Edge Banding Machine

SE-2015B double sides edge banding, application for one time finished two sides edging. Suitable for standard product and quantity production requirement. Main function : 2 SETS of Gluing & edging, end trimming, rough trimming, fine trimming, scraping, buffing.

-

SE-206P Heavy-duty High Speed Automatic Edge Banding Machine

SE-206P edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Max. feeding speed: 26m/min. Main Functions: Pre-milling, Quick melt gluing & Edging, pneumatic end trimming, pneumatic trimming1, pneumatic trimming2, pneumatic scrapping1, pneumatic scrapping2, buffing1, buffing 2.

-

SE-2106B Automatic Double Sides Edge Banding Machine -

SE-2015B double sides edge banding, application for one time finished two sides edging. Suitable for standard product and quantity production requirement. Main function : 2 SETS of Pre-milling, gluing & edging, end trimming, rough trimming, fine trimming, scraping, buffing.

-

SE-208B Heavy-duty High Speed Automatic Edge Banding Machine

SE-208P edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Main Functions: Pre-milling, quick melt gluing & Edging, pressure roller glue scraping device, pneumatic trimming1 , pneumatic trimming2, corner rounding, pneumatic scraping1, pneumatic scraping 2, edge band clamping unit, buffing1, buffing 2.

-

SE-208TA Heavy-duty High Speed Automatic Edge Banding Machine

SE-208TA edge banding machine is specially designed for the full automatic edge banding for all kinds of woodworking boards. Main Functions: Pre-milling, quick melt gluing & Edging1 , quick melt gluing & Edging2, pressure roller glue scraping device, pneumatic trimming1 , pneumatic trimming2, corner rounding, pneumatic scraping1, pneumatic scraping 2, edge band clamping unit, buffing1, buffing 2.

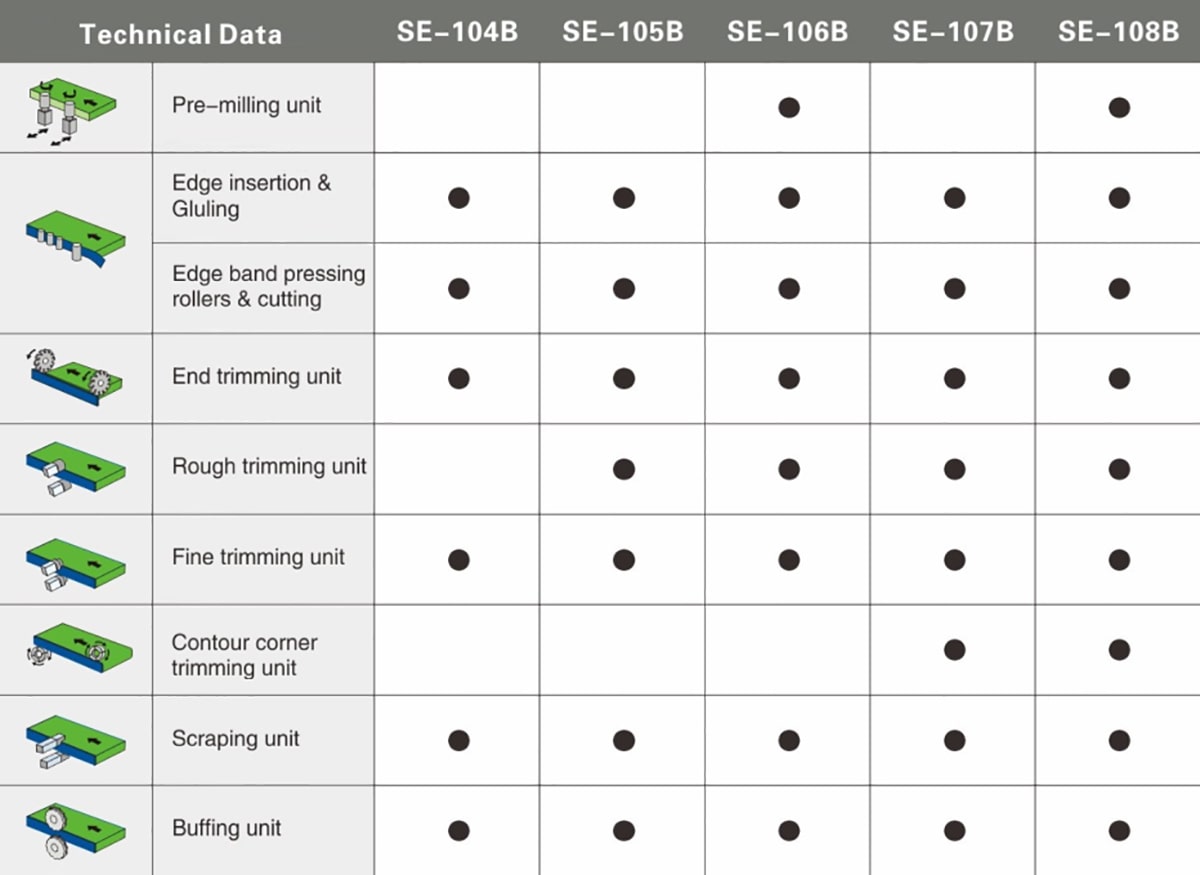

Technical Data

SE1 series edge banding machine available in a variety of configurations optional, satisfy your different production requirements.

SE-XXXBA Pneumatic Trimming (Optional)

Pneumatic Controlling System (Optional): 4 different thickness of edge band can be automatic adjusted by touchscreen control.

CONTACT US

GUANGDONG SANDAR CNC MACHINERY CO., LTD.

We provide customers with quality products and services.

If you would like to leave us a comment please go to contact us

© 2024 GUANGDONG SANDAR CNC MACHINERY CO., LTD. All rights received.